Posted At: Aug 14, 2025 - 745 Views

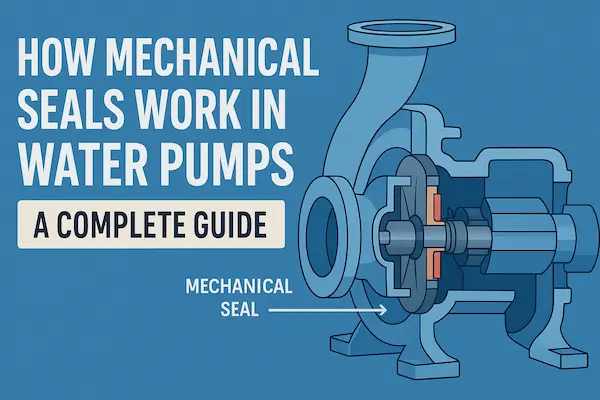

How Mechanical Seals Work in Water Pumps: A Complete Guide

Introduction

In the world of water pump systems, mechanical seals are the unsung heroes that prevent leaks, protect components, and ensure smooth operation. Without them, pumps would face frequent downtime, costly repairs, and reduced efficiency. This guide explains how mechanical seals work in water pumps, covering their components, working principles, benefits, and maintenance tips so you can maximize your pump’s lifespan.

What Is a Mechanical Seal in a Water Pump?

A mechanical seal is a device that seals the rotating shaft of a pump to prevent water or fluid from leaking out along the shaft. It forms a barrier between the pump’s rotating shaft and stationary pump housing, ensuring the fluid stays inside while the shaft can spin freely.

Why Are Mechanical Seals Important in Water Pumps?

Leak Prevention – Stops fluid from escaping, protecting the motor and surrounding equipment.

Efficiency – Maintains proper pressure and reduces energy loss.

Protection – Prevents water contamination and internal corrosion.

Durability – Extends the pump’s service life by reducing wear on components.

Main Components of a Mechanical Seal

Rotating Face – Attached to the shaft and rotates with it.

Stationary Face – Fixed to the pump housing and remains still.

Secondary seals—such as O-rings, gaskets, or bellows—serve to block leakage between the seal faces and the pump components.

Spring or Bellows – Keeps the faces pressed together to maintain a tight seal.

Metal Parts – Provide structural support and ensure correct alignment.

How Mechanical Seals Work in Water Pumps

The principle is simple but effective:

Sealing Faces in Contact – The rotating and stationary seal faces press tightly together, creating a seal.

Lubrication by the Pumped Fluid – A thin fluid film forms between the faces, reducing friction and heat.

Pressure Control – The springs or bellows maintain consistent pressure as the shaft rotates.

Leakage Prevention – This setup prevents water from escaping along the shaft while allowing smooth rotation.

Types of Mechanical Seals Used in Water Pumps

Single Mechanical Seals – Simple design, ideal for clean water applications.

Double Mechanical Seals – Best for high-pressure or hazardous fluids.

Cartridge Mechanical Seals – Pre-assembled for easy installation and reduced maintenance time.

Split Mechanical Seals – Allow installation without dismantling the pump.

Common Problems with Mechanical Seals in Water Pumps

Dry Running – Operating without fluid can overheat the seal faces.

Improper installation - such as misalignment or excessive tightening—can lead to premature failure.

Contaminated Fluid – Dirt or solids can damage the sealing faces.

Excessive Vibration – Can wear out seals prematurely.

Maintenance Tips for Mechanical Seals

Always ensure proper lubrication.

Avoid running the pump dry.

Regularly inspect seals for wear or leaks.

Use the correct seal type for the fluid and operating conditions.

Keep the pump and surrounding area clean.

Benefits of Using Mechanical Seals in Water Pumps

Longer pump life

Reduced leakage and environmental risk

Lower maintenance costs

Higher efficiency and performance

Conclusion

Understanding how mechanical seals work in water pumps is key to improving pump performance, preventing leaks, and reducing maintenance costs. Whether you use a single, double, cartridge, or split seal, proper selection, installation, and care will ensure reliable pump operation for years.

Frequently Asked Questions

1. How long do mechanical seals last in water pumps?

With regular maintenance, a mechanical seal can last between 2 and 5 years, depending on the operating conditions.

2. Can I replace a mechanical seal myself?

It’s possible if you have technical knowledge, but professional installation ensures correct alignment and longer seal life.

3. What happens if a mechanical seal fails?

You may experience leakage, reduced efficiency, and possible damage to pump components.

4. Are all mechanical seals suitable for water pumps?

No — the seal must be selected based on the pump’s operating pressure, temperature, and the properties of the fluid being handled.