Posted At: Aug 20, 2025 - 4,357 Views

Mechanical Seal Parts: Basic Parts Names and Their Functions

Introduction

Mechanical seals are critical components in pumps, compressors, and rotating equipment, ensuring leak-free operation and long-lasting performance. While many users know what a seal does, fewer understand the mechanical seal parts that make up the assembly. Each part of a seal plays a unique role in preventing leakage, reducing wear, and maintaining system efficiency.

In this guide, we’ll break down the basic mechanical parts names, explain the parts of a seal, and explore their functions in detail.

What Are Mechanical Seal Parts?

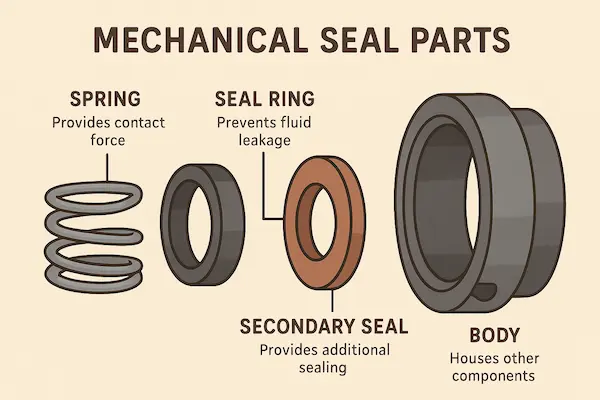

A mechanical seal is not a single component but an assembly of different precision-engineered parts. Together, these parts form a sealing system that prevents fluid leakage between a rotating shaft and the stationary housing of equipment.

Understanding the parts of a seal helps operators and maintenance teams troubleshoot issues, choose replacements, and ensure reliable pump performance.

Basic Mechanical Seal Parts Names and Their Functions

Below are the key mechanical seal parts and what they do:

1. Seal Faces (Primary Ring & Mating Ring)

Description: The most critical sealing surfaces, usually made of carbon, ceramic, silicon carbide, or tungsten carbide.

Function: One face rotates with the shaft (rotary seal face), and the other remains stationary. The two faces run against each other to form the sealing interface.

Importance: High precision ensures minimal leakage and prevents wear.

2. Secondary Seals (O-Rings, Gaskets, and Bellows)

Description: Elastomeric components like O-rings, gaskets, or rubber bellows.

Function: Provide secondary sealing between seal faces and metal parts to prevent bypass leakage.

Importance: Absorb vibrations, accommodate misalignment, and handle thermal expansion.

3. Spring or Multiple Springs

Description: A single coil spring or multiple small springs.

Function: Keeps the seal faces in constant contact under varying pressure conditions.

Importance: Ensures consistent sealing performance, even with shaft movement or pressure fluctuations.

4. Retainer (Seal Housing / Gland Plate)

Description: The outer casing or gland that holds all parts of a seal together.

Function: Positions the seal correctly on the pump shaft and allows for proper compression of seal faces.

Importance: Protects inner components and provides stability.

5. Rotary Seal Ring (Rotating Component)

Description: Attached to and rotates with the pump shaft.

Function: Works with the stationary ring to form the main sealing surface.

Importance: Handles friction, temperature changes, and pressure variations.

6. Stationary Seal Ring (Seat / Mating Ring)

Description: Mounted in the seal gland or housing, remains stationary.

Function: Acts as the counter-face to the rotary seal ring.

Importance: Together with the rotary face, ensures a reliable fluid-tight seal.

7. Metal Parts (Collars, Set Screws, and Drive Pins)

Description: Small but essential mechanical parts.

Function: Secure the seal to the shaft, transmit torque, and maintain alignment.

Importance: Prevent slippage and misalignment of the seal assembly.

Why Understanding Mechanical Seal Parts Matters

Knowing the basic mechanical parts names and their functions helps industries:

Improve Maintenance – Identifying worn-out seal parts ensures quick repairs.

Enhance Reliability – Using the correct seal faces and elastomers prevents downtime.

Reduce Costs – Preventing leakage lowers fluid loss and energy consumption.

Ensure Safety – Proper seal parts reduce the risk of fluid or gas leakage in hazardous industries.

Common Materials Used in Mechanical Seal Parts

Seal Faces: Carbon, silicon carbide, tungsten carbide, ceramic

Secondary Seals: Viton, Nitrile (NBR), EPDM, PTFE

Springs & Metal Parts: Stainless steel, Hastelloy, Inconel

Gland/Retainer: Stainless steel, Alloy steels

The right material selection depends on fluid type, temperature, pressure, and industry requirements.

Conclusion

Mechanical seals are more than just sealing devices — they are assemblies of multiple precision-engineered parts. By understanding the mechanical seal parts, such as seal faces, secondary seals, springs, and gland plates, industries can make informed choices, improve pump reliability, and extend equipment life.

Knowing the parts of a seal and the basic mechanical parts names also makes maintenance and troubleshooting easier, ensuring long-term efficiency and safety in industrial operations.