Posted At: Jul 03, 2025 - 1,726 Views

Mechanical Seal Working Principle Explained with Diagrams

Mechanical seals are essential components in pumps, compressors, mixers, and other rotating equipment where leakage control is critical. Their main function is to stop fluid within the system from escaping along the rotating shaft. In this blog, we will explain how a mechanical seal works, dive into the mechanical seal working principle, and provide clear diagrams of mechanical seals to help you understand their operation. Whether you're a maintenance engineer, plant operator, or equipment supplier, this guide will give you a complete understanding of mechanical seal functions.

What Is a Mechanical Seal?

A mechanical seal is a device that joins systems or mechanisms together by preventing leakage, containing pressure, or excluding contamination. It operates by forming a seal at the junction where a rotating shaft moves through a stationary housing, or in some cases, between two rotating elements.

Mechanical seals are commonly used in:

- Centrifugal pumps

- Mixers and agitators

- Compressors

- Reactors and blenders

They are more reliable than traditional packing seals, require less maintenance, and provide longer operational life.

Mechanical Seal Working Principle

At the core of the mechanical seal working principle lies the concept of two flat surfaces pressed together: one rotates with the shaft (the rotating face), and the other remains stationary (the stationary face). These faces are precisely machined to ensure minimal leakage.

Here’s how it works:

Primary Sealing Faces

One face is attached to the shaft (rotating seal face).

The other is fixed to the pump housing (stationary seal face).

These faces are pressed together with a spring or bellows and lubricated by a fluid film.

Secondary Seals

O-rings or gaskets are used to seal between the components and prevent leakage through the mating parts.

Spring Mechanism or Bellows

Provides axial force to keep the sealing faces together even if there is shaft movement or wear.

Leakage Control

A very thin fluid film (usually from the pumped product) forms between the faces to reduce wear and heat.

This fluid film ensures long life while keeping leakage at a minimal, often invisible, level.

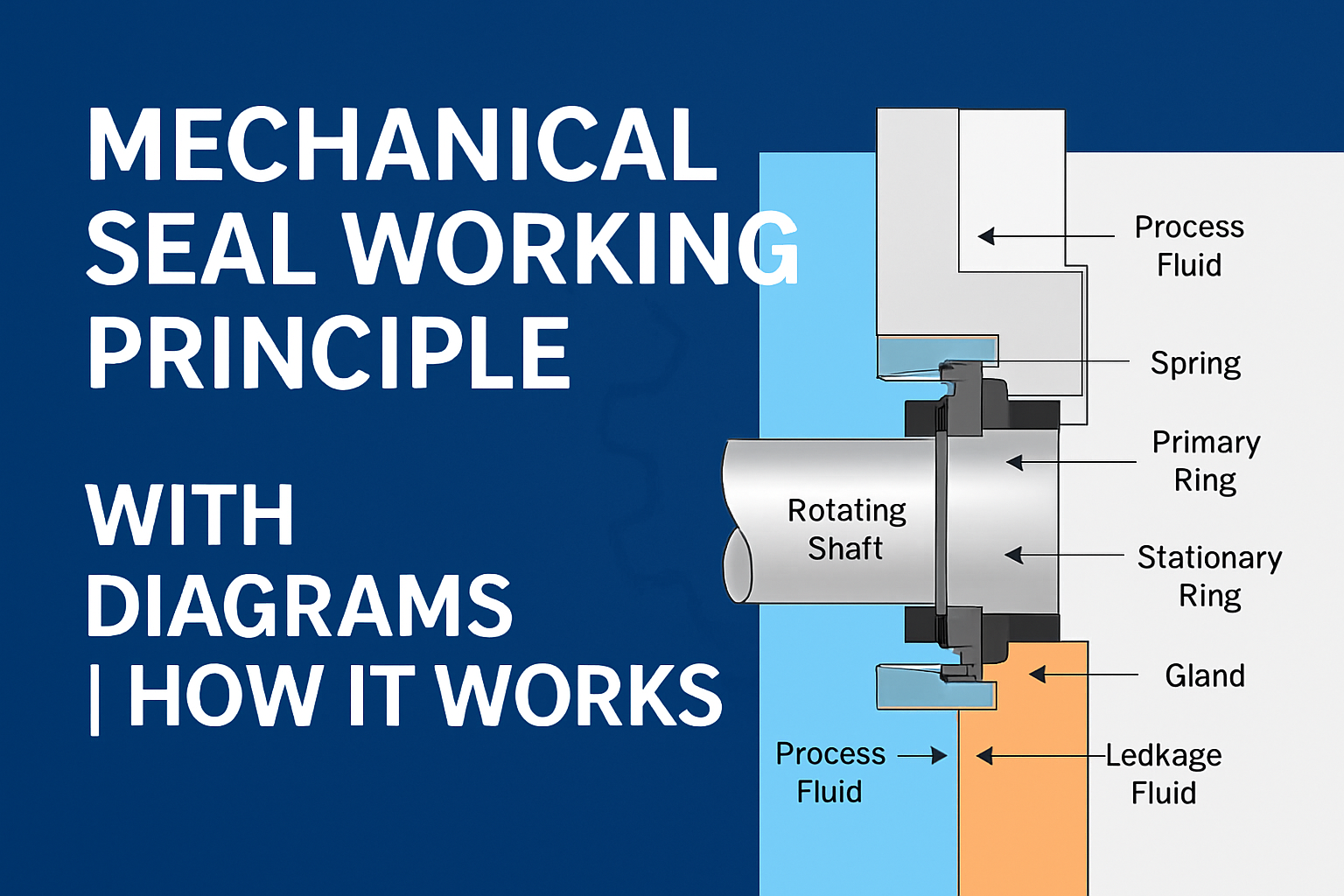

Mechanical Seal Diagram

Below is a simplified diagram that shows the construction and layout of a typical mechanical seal:

Key Mechanical Seal Parts Labeled in the Diagram:

Rotating face (seal ring)

Stationary face (seat)

O-ring or gasket (secondary seal)

Spring or bellows

Shaft sleeve

Gland plate or seal housing

The rotating and stationary faces are the heart of the seal and their alignment is key to proper sealing performance.

Types of Mechanical Seals

Understanding the working principle also involves recognizing the different types of mechanical seals, which include:

Pusher Type Seals

Use springs to push the sealing faces together. They accommodate axial shaft movement.

Non-Pusher Type Seals (Bellows Seals)

Use metal or elastomer bellows, ideal for high-temperature applications.

Cartridge Seals

Pre-assembled units with all components — easy to install and reduce installation errors.

Component Seals

Individual seal components assembled during installation.

Balanced Seals

Handle higher pressures by reducing the closing force on the seal faces.

Unbalanced Seals

Simpler and more cost-effective, used in lower-pressure applications.

Advantages of Using Mechanical Seals

Superior Leakage Control

Offers better sealing performance than gland packing.

Increased Equipment Lifespan

Reduces shaft wear and maintenance costs.

Operational Efficiency

Low friction results in energy savings.

Safer Operations

Especially important in sealing hazardous or flammable fluids.

Applications of Mechanical Seals

Mechanical seals are widely used across industries, including:

- Oil and Gas

- Pharmaceutical

- Chemical Processing

- Water Treatment

- Food and Beverage

- Pulp and Paper

Choosing the right mechanical seal depends on application parameters like pressure, temperature, fluid type, and shaft speed.

Mechanical Seal Maintenance Tips

To ensure longer seal life and reliable performance:

Maintain clean and well-lubricated systems

Avoid dry running of pumps

Use proper alignment and installation techniques

Regularly inspect seal faces and springs

Monitor for vibration and shaft deflection

Conclusion

Understanding the mechanical seal working principle is vital for selecting the right seal for your equipment and ensuring efficient, leak-free operation. With properly installed mechanical seals, industries can reduce downtime, avoid hazardous leaks, and improve system reliability.

By referring to the mechanical seal diagram and knowing each component's function, operators can make informed decisions about installation, troubleshooting, and replacement.